Inventory mismanagement is one of the biggest challenges faced by steel manufacturers today. From overstocking to production delays, poor inventory control can cost companies time and money.

In this article, we’ll explore how Steel Manufacturing ERP helps solve these issues by streamlining inventory processes, improving accuracy, and providing real-time visibility. Whether you’re struggling with manual tracking or looking to upgrade your current system, this guide will show how ERP can transform your inventory management.

Table of Contents

- Understanding the Basics of Steel Manufacturing ERP

- ERP Role in Inventory Management for Steel Manufacturing:

- How ERP Minimizes Stockouts and Overstocks in Steel Manufacturing?

- How ERP Minimizes Stockouts and Overstocks in Steel Manufacturing?

- Key Benefits of Steel Manufacturing ERP for Inventory Control

- Inventory Optimization with ERP:

- Measuring the Success of ERP in Inventory Management:

- Top Steel Manufacturing ERP Software Solutions for Inventory Management

- Customization of ERP Systems for the Steel Industry

- Key ERP Features for Improving Inventory Visibility

- Case Study: ERP Implementation in Kamran Steel

- Conclusion:

Understanding the Basics of Steel Manufacturing ERP

Steel Manufacturing ERP is more than just software—it’s a smart solution designed to simplify the complex day-to-day of running a steel business. Instead of juggling spreadsheets, paper trails, or disconnected tools, ERP brings everything into one central system.

So, what does it really do?

Here’s a quick breakdown:

- Inventory Management: Tracks raw materials, semi-finished, and finished goods in real-time.

- Production Planning: Helps schedule jobs, allocate resources, and avoid bottlenecks.

- Finance & Accounting: Keeps tabs on costs, billing, and financial reporting.

- Human Resources: Manages employee data, payroll, and shift planning.

Why it matters:

With real-time data and automation, teams can make faster, better decisions—reducing waste, avoiding stock outs, and staying ahead of demand.

In short, Manufacturing ERP for Steel Industry is like giving your factory floor a brain—it keeps everything connected and running smarter.

ERP Role in Inventory Management for Steel Manufacturing:

Effective inventory management is essential for all manufacturing industries, including steel. With ERP systems like Odoo and ERPNext, we provide real-time inventory data to optimize your steel production operations.

How ERP Minimizes Stockouts and Overstocks in Steel Manufacturing?

Keeping track of steel inventory—from raw materials to finished coils—is no small task. One wrong number, and you’re either overstocked or scrambling for supplies. That’s where ERP makes a big difference.

Here’s how it helps:

- Tracks Everything in One Place

- From scrap metal to final products, ERP logs every item’s movement through production.

- Real-Time Updates

- As soon as something is used, scanned, or moved, it’s recorded instantly—no more guesswork or outdated spreadsheets.

- Fewer Manual Errors

- Automation reduces the need for manual entry, which means fewer mistakes and better accuracy.

- Connected to the Supply Chain

- ERP integrates with vendors and logistics, so you know exactly what’s coming in and going out.

With ERP, your inventory isn’t a mystery—it’s a clear, real-time snapshot you can trust. And that clarity? It saves time, money, and a whole lot of headaches.

How ERP Minimizes Stockouts and Overstocks in Steel Manufacturing?

Balancing inventory in steel manufacturing can feel like walking a tightrope—too little stock causes production delays, while too much ties up cash and space. ERP systems help strike that perfect balance with smart tools designed to keep inventory levels just right.

Here’s how ERP steps in:

- Inventory Optimization

- ERP monitors usage trends and production needs to help you maintain ideal stock levels at all times.

- Automated Reorder Alerts

- When materials drop below a set threshold, the system automatically notifies purchasing—no more surprise shortages.

- Forecasting Made Easy

- ERP uses historical data and demand patterns to predict future needs, helping you avoid over-ordering.

- Real-Time Visibility

- Live tracking of inventory movements keeps everyone on the same page, from the shop floor to procurement.

With ERP, steel manufacturers can stop guessing—and start planning with confidence.

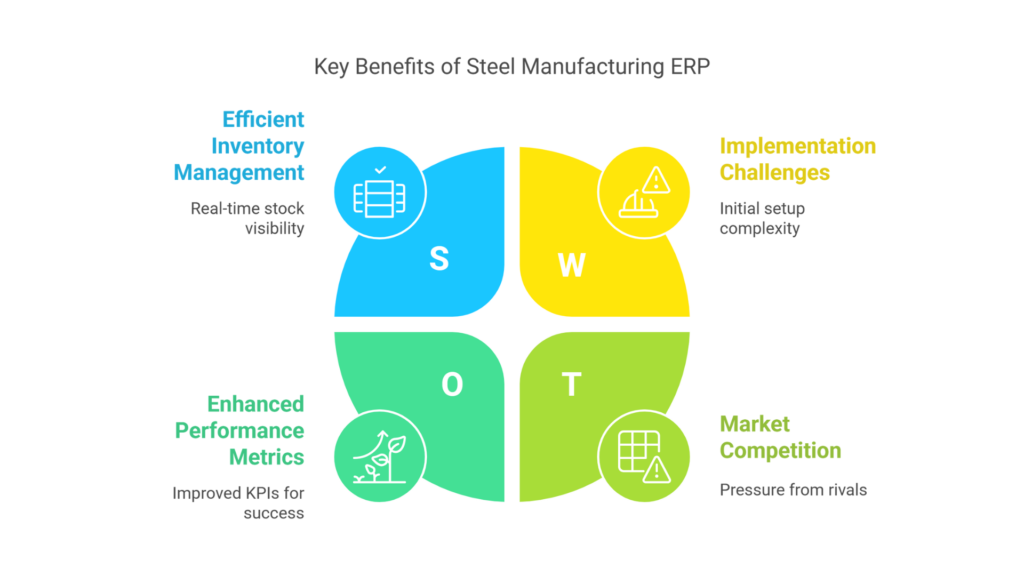

Key Benefits of Steel Manufacturing ERP for Inventory Control

When it comes to inventory control, Steel Manufacturing ERP offers powerful, real-time solutions that go beyond basic organization. It empowers manufacturers to manage stock more efficiently, reduce waste, and cut costs. Here are some key benefits:

Inventory Optimization with ERP:

In the steel industry, wasted materials and poor inventory planning can lead to massive losses. That’s where ERP steps in—not just to organize, but to optimize.

With ERP, you gain real-time visibility into what’s coming in, what’s going out, and what’s just sitting idle. This helps you:

- Eliminate unnecessary overstocking

- ERP tracks inventory usage patterns to ensure you’re not buying more than you need.

- Reduce material wastage

- By aligning inventory with production schedules, ERP helps minimize leftover scrap or expired materials.

- Streamline workflows

- Automated processes reduce human error, cut down delays, and improve how inventory flows through the system.

The result? Fewer mistakes, less waste, and a smoother, more efficient operation—saving both time and money.

Measuring the Success of ERP in Inventory Management:

So, how do you know your ERP system is actually working?

Look at these key performance indicators (KPIs):

- Cost Savings

- Reduced inventory holding costs and less capital tied up in unused stock.

- Order Accuracy

- Fewer errors in inventory records and order fulfillment.

- Time Efficiency

- Automated tasks free up staff to focus on value-added work.

- Stock Turnover Rate

- A healthy turnover rate means materials are moving efficiently through the system.

When these KPIs improve, you know your ERP investment is paying off—not just in numbers, but in peace of mind.

Top Steel Manufacturing ERP Software Solutions for Inventory Management

Customization of ERP Systems for the Steel Industry

Steel manufacturing isn’t a one-size-fits-all process, and neither should be your ERP system. Customization is key to ensuring that the software addresses the specific challenges of your business.

- Tailored to Your Needs

- Every steel manufacturer has unique workflows, from raw material sourcing to production. Customizing your ERP ensures it aligns perfectly with these processes, so you’re not forced to adapt to rigid software limitations.

- Scalability for Growth

- As your business expands, so should your ERP. Scalable ERP systems allow you to add new features, users, and locations without disrupting operations. Whether you’re opening new plants or expanding globally, your system grows with you.

With ERP customization and scalability, you get a tool that adapts to your evolving needs, making it a long-term investment that evolves alongside your business.

Key ERP Features for Improving Inventory Visibility

Real-time inventory visibility is essential in today’s fast-paced steel industry. ERP systems include powerful features designed to give you full control over your stock.

- Barcode Scanning and RFID Integration

- By scanning and tracking items automatically, these technologies ensure inventory is updated instantly, reducing human error and manual entry.

- Real-Time Reporting

- With live data at your fingertips, you can make quick, informed decisions—whether adjusting production or planning new stock orders.

- Comprehensive Reporting Tools

- ERP systems provide detailed, data-driven insights that help you spot trends, forecast demand, and optimize inventory levels.

With these ERP features, managing your steel inventory becomes a seamless, efficient process that empowers better decision-making and minimizes costly errors.

Case Study: ERP Implementation in Kamran Steel

Kamran Steel, a leading steel manufacturer in Pakistan, was struggling with severe inventory mismanagement. Manual tracking and inconsistent stock levels led to both overstocking and shortages—hurting their profitability and causing delays in production.

Challenges Faced:

- Overstocking of raw materials, tying up capital and storage space.

- Stockouts of critical materials, leading to production halts and missed deadlines.

- Manual inventory tracking, resulting in frequent human errors.

How ERP Solved These Problems:

- Real-Time Inventory Updates: Kamran Steel integrated an ERP system that provided live tracking of materials, from raw inputs to finished goods.

- Automated Replenishment: The ERP’s automated reorder alerts ensured that stock levels were maintained at optimal levels, reducing both excess stock and shortages.

- Centralized Data: With everything in one system, Kamran Steel could view detailed reports and make quick decisions based on accurate, up-to-date data.

Real-World Impact on Inventory Control

After implementing ERP, Kamran Steel saw significant improvements:

- Cost Reduction: A 15% reduction in inventory holding costs as excess stock was minimized.

- Stock Optimization: Raw material levels were aligned with production needs, reducing waste and shortages.

- Process Improvements: The Inventory management system became more efficient, allowing for faster decision-making and smoother operations.

Kamran Steel’s success story highlights how ERP can transform inventory control, bringing measurable results in cost savings, efficiency, and reduced risk.

Conclusion:

In conclusion, Steel Manufacturing ERP is a game-changer when it comes to addressing inventory mismanagement in the steel industry. With real-time tracking, automated replenishment, and enhanced data visibility, ERP systems streamline inventory processes, reduce waste, and ensure more accurate stock levels.

Adopting an ERP solution is an essential step toward improving your inventory control and boosting efficiency. Infintrix Technologies specializes in ERP implementation tailored to the unique needs of the steel industry. If you’re ready to optimize your operations, consulting with our team of experts is the perfect next step. Don’t wait—take control of your inventory today and drive your business forward with the power of ERP.