As the demand for sustainable fashion grows, textile manufacturers face increasing pressure to reduce waste, improve transparency, and operate more responsibly. However, outdated systems and fragmented processes often hold them back. Textile Manufacturing ERP provides a smarter way forward.

By integrating production, procurement, inventory, and supply chain management in real time, Cloud ERP systems help manufacturers minimize waste, optimize resource use, and support more sustainable practices. In this article, we’ll explore how ERP for textile and apparel helps businesses to innovate, operate efficiently, and stay ahead in a sustainability-focused industry.

Table of Contents

- What is Textile Manufacturing ERP?

- Key Ways ERP Improves Textile Manufacturing:

- Smart Inventory Control with ERP:

- Overcoming ERP Integration Challenges:

- Business Benefits & ROI of Textile ERP:

- Choosing the Right Textile ERP Vendor in Pakistan:

- FAQs on Textile Manufacturing ERP

- Conclusion:

What is Textile Manufacturing ERP?

Textile Manufacturing ERP Software is specialized software designed to handle the unique complexities of textile and apparel production, such as group tracking, fabric specs, dye lot control, and seasonal demand.

Unlike generic ERP software, which often lacks industry-specific workflows, a textile-focused ERP aligns seamlessly with your production cycles, inventory types, and control standards.

Trying to force a general ERP into a textile business often leads to clunky workarounds, missed insights, and limited flexibility. With the right ERP built for textiles, you gain real-time control, reduce waste, and streamline manufacturing operations from loom to logistics.

Key Ways ERP Improves Textile Manufacturing:

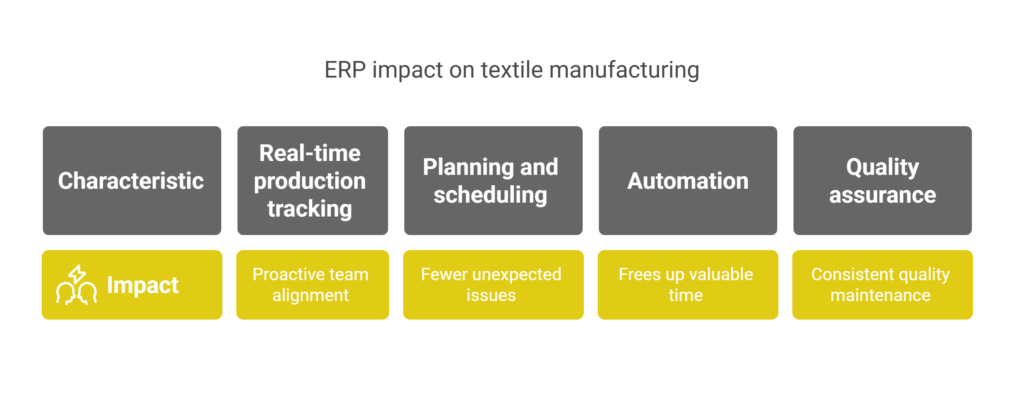

A well-implemented Textile Manufacturing ERP does more than manage data—it transforms how you plan, produce, and deliver. From real-time visibility to smart automation, ERP systems give manufacturers the agility they need to stay ahead in a competitive, fast-moving industry.

- Real-time production tracking keeps teams aligned and proactive. With instant data from the shop floor, you can spot delays early, manage resources better, and reduce downtime.

- Better planning and scheduling mean fewer surprises. ERP platforms analyze capacity, raw materials, and deadlines to help you schedule efficiently, so orders are completed on time and within budget.

- Automation in repetitive processes like order entry, inventory updates, and compliance reporting frees up time and reduces manual errors. This leads to smoother workflows and better use of skilled labor.

- Improved quality assurance is built into every stage. From fabric specs to final inspection, ERP systems standardize processes and record results in real time—helping you maintain consistent quality control and customer trust.

Whether you’re aiming to increase your supply chain output, reduce waste, or enhance decision-making, textile ERP automation backed by real-time data delivers measurable improvements across your operation.

Smart Inventory Control with ERP:

Inventory issues can quietly drain profits—especially in textile manufacturing, where raw materials, fabric rolls, and finished goods all move at different speeds. With the right ERP solution for textile inventory control, you gain complete visibility and control over every unit in real time.

ERP tracks stock levels across warehouses, production lines, and retail channels, helping you avoid both overstocking and costly shortages. Automated restocking alerts ensure you’re always prepared, while smart storage planning improves space utilization and handling efficiency.

ERP turns inventory management from a headache into a competitive edge by minimizing waste, reducing manual checks, and syncing inventory with production schedules.

Overcoming ERP Integration Challenges:

Implementing a Textile Manufacturing ERP can feel daunting, but tackling common hurdles head‑on can optimize a smooth transition and fast ROI:

- Legacy Software & Data Migration: Convert old spreadsheets and siloed systems into a unified database without losing vital production history.

- Change Management in Traditional Setups: Engage teams early, offer hands‑on training, and showcase quick wins to build confidence and buy‑in.

- Choosing Scalable Solutions: Select an ERP for textiles that grows with your business—modular features, cloud deployment options, and flexible licensing make future expansions painless.

Ready to breeze past integration roadblocks? Partner with experts who understand challenges in textile ERP integration and turn obstacles into opportunities.

Business Benefits & ROI of Textile ERP:

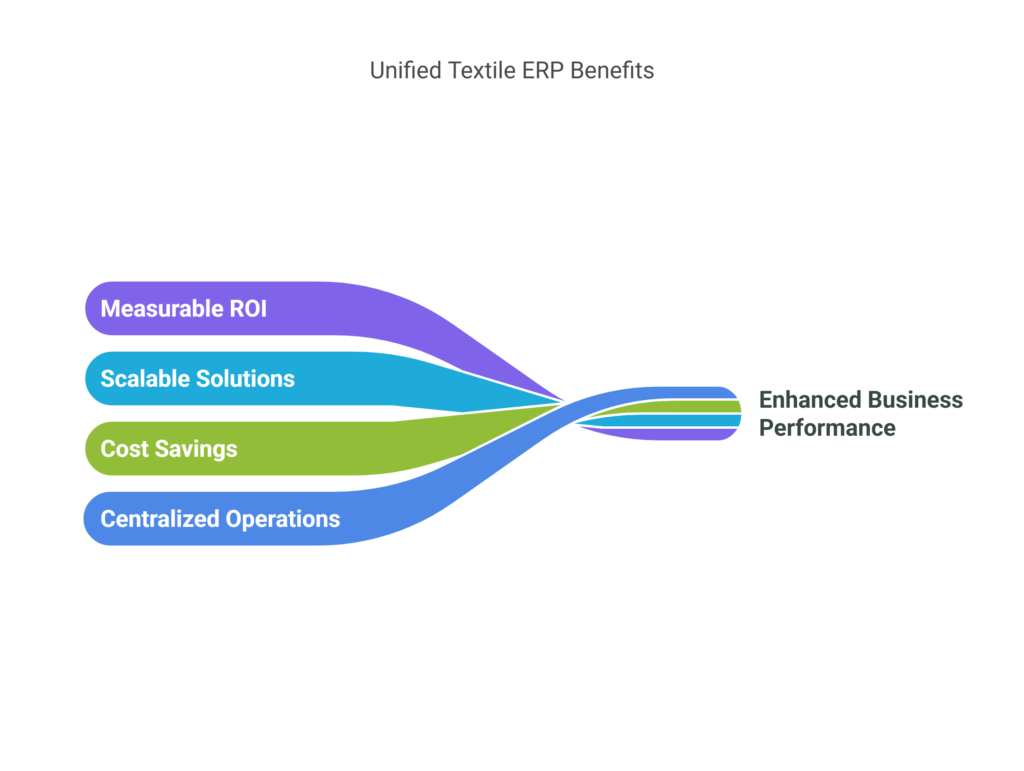

A unified Textile Manufacturing ERP delivers tangible business benefits and a strong ROI of textile manufacturing ERP investments:

- Centralized Operations & Team Coordination

- By integrating sales, production, inventory, and finance, teams share a single source of truth—eliminating miscommunication and speeding decision‑making.

- Cost Savings Through Reduced Errors & Delays

- Automated workflows cut manual data entry, minimize stockouts, and prevent costly production hiccups—freeing up budget for growth.

- Scalable Solutions for Every Manufacturer

- Whether you’re a large mill or exploring ERP systems for small textile manufacturers, modular deployments let you start simple and expand features as needs evolve.

- Measurable ROI & Long‑Term Impact

- Track key metrics—like order‑fulfillment rates, inventory turnover, and margin improvements—to quantify the benefits of integrated textile ERP systems. Dashboards and real‑time reports make it easy to demonstrate payback in months, not years.

Experience smoother operations, tighter cost control, and data‑driven insights that power your next growth phase. Ready to see your ROI skyrocket? Let’s discuss how Textile Manufacturing ERP can transform your bottom line.

Choosing the Right Textile ERP Vendor in Pakistan:

Choosing the right Textile Manufacturing ERP vendor can make or break your digital transformation. Here’s how to ensure you pick a partner that delivers real value:

Must‑Have Textile ERP System Features

- Inventory Control: Batch tracking, roll-level visibility, and automated restocking alerts

- Quality Management: In-process inspections, defect tracking, and compliance reporting

- Production Planning: Capacity scheduling, work orders, and real‑time shop‑floor dashboards

- Reporting & Analytics: Customizable KPI dashboards, trend analysis, and exportable reports

Industry‑Specific Expertise

Look for vendors with proven experience in textile processes—yarn sourcing, dyeing, weaving, and finishing—to avoid generic solutions that require costly customizations.

Key Questions to Ask

- How do you handle data migration from legacy systems?

- What’s your implementation timeline for a mid‑sized mill?

- Which modules are cloud‑based vs. on‑premise?

- Can you support ongoing upgrades and local compliance?

For manufacturers in Pakistan and around the world, Infintrix Technologies stands out as the go‑to Textile ERP partner—offering deep industry knowledge, scalable solutions, and unmatched support. Ready to streamline your operations? Let’s talk.

FAQs on Textile Manufacturing ERP

Q1. Is ERP suitable for small textile manufacturers?

Yes — many cloud-based ERP systems offer modular plans that are affordable, scalable, and perfect for small units.

Q2. How long does ERP implementation take in a textile factory?

Implementation time varies from a few weeks to several months, depending on business size, data migration, and customization needs.

Q3. Can ERP systems handle dyeing and batch tracking?

Absolutely. Textile-specific ERPs include modules for dyeing, batch processing, lot traceability, and more.

Q4. What’s the ROI timeline for textile ERP?

Most manufacturers start seeing ROI within 6–12 months through savings in labor, time, reduced waste, and better delivery cycles.

Q5. How do I choose the best ERP software for textile manufacturing?

Look for industry-specific features, ease of use, real-time reporting, vendor support, and scalability to match your business growth.

Conclusion:

Textile Manufacturing ERP isn’t just a software upgrade—it’s a strategic shift that turns difficulty into clarity. By centralizing operations, reducing waste, and enabling real-time decision-making, ERP systems bring control, speed, and scalability to textile businesses of all sizes.

If your production feels chaotic, your inventory is bloated, or your teams are disconnected, it’s time to rethink your workflow. Start by evaluating where your current processes fall short and explore ERP solutions built specifically for the textile industry.

The right partner—like Infintrix Technologies—can help you unlock efficiency, growth, and long-term profitability.