Managing a warehouse without seamless system integration leads to inventory errors, delayed orders, and operational inefficiencies. Without WMS ERP Integration, businesses struggle with disconnected data, manual processes, and increased costs—hindering growth. The good news? A well-executed WMS ERP integration eliminates these challenges by centralizing data, improving accuracy, and enhancing overall efficiency.

In this guide, we’ll break down the integration process step by step, ensuring your business optimizes operations and minimizes disruption. Whether you’re new to system integration or refining an existing setup, this guide will help you achieve a smooth and successful transition.

Understanding WMS and ERP Systems:

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is specialized software designed to optimize warehouse operations by improving inventory tracking, order fulfillment, and overall logistics efficiency. It helps businesses maintain real-time visibility of stock levels, automate workflows, and reduce manual errors.

By streamlining warehouse processes, a WMS ensures faster order processing, better space utilization, and improved accuracy in shipments.

What is an Enterprise Resource Planning (ERP) System?

An Enterprise Resource Planning (ERP) system integrates core business functions such as finance, procurement, human resources, and inventory management into a single platform. It enhances operational efficiency by providing centralized data access, automating repetitive tasks, and improving decision-making.

ERP systems bridge the gap between various departments, ensuring seamless communication and data flow across the organization.

Importance of WMS ERP Integration

Integrating WMS and ERP systems synchronizes warehouse and business operations, resulting in improved supply chain efficiency, cost savings, and better customer satisfaction. With a well-integrated solution, businesses can reduce delays, eliminate data silos, and gain real-time insights for smarter decision-making.

Infintrix Technologies specializes in implementing WMS ERP integration, ensuring a smooth transition that maximizes efficiency and profitability.

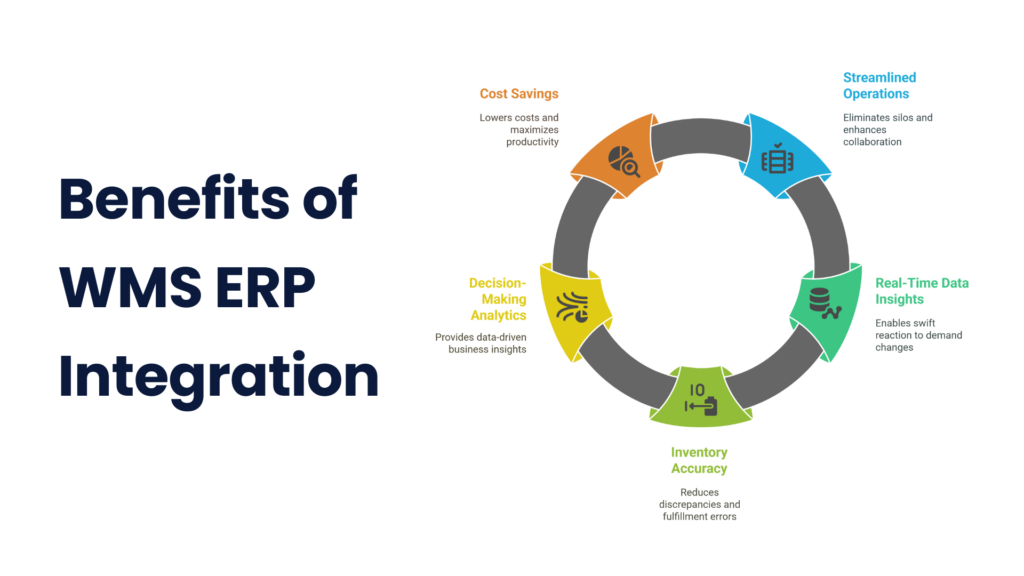

Benefits of Integrating WMS and ERP

Streamlined Business Operations:

Integrating Warehouse Management Systems (WMS) with Enterprise Resource Planning (ERP) solutions creates a seamless flow of data across departments. This eliminates silos, reduces manual processes, and enhances collaboration between inventory, sales, and finance teams. By automating workflows, businesses can fulfill orders faster, minimize errors, and improve overall operational efficiency.

Accurate, Real-Time Data Insights

A well-integrated WMS and ERP system enables real-time inventory tracking, order status updates, and efficient distribution management This ensures businesses can react swiftly to demand fluctuations, prevent stockouts, and optimize warehouse space utilization.

Enhanced Inventory & Order Accuracy

With automation reducing human intervention, inventory discrepancies and order fulfillment errors significantly decrease. Barcoding, RFID, and automated tracking help maintain precise stock levels, ensuring customers receive the right products on time.

Improved Decision-Making with Data Analytics

Businesses gain valuable insights from integrated analytics, helping them make data-driven decisions. Predictive analytics in ERP systems can forecast demand, optimize procurement, and improve supplier relationships.

Cost Savings:

By reducing labor-intensive tasks, eliminating redundant data entry, and improving operational efficiency, businesses can lower costs while maximizing productivity. A streamlined supply chain system leads to faster order processing and higher customer satisfaction.

Preparing for WMS ERP Integration

Evaluating Your Current Systems

Before integrating your Warehouse Management System (WMS) with an Enterprise Resource Planning (ERP) solution, assess your existing infrastructure. Identify inefficiencies, data gaps, and system limitations. Understanding how your current setup operates will help pinpoint areas that need improvement and ensure a smoother transition.

Setting Clear Integration Goals

Define what you aim to achieve with the integration—whether it’s improving order accuracy, streamlining warehouse operations, or enhancing real-time data visibility. Clear objectives will guide the integration process and help measure its success.

Choosing the Right Integration Method

Depending on your business needs, you can opt for direct integration, middleware solutions, or cloud-based APIs. Each method has its advantages, and selecting the right one ensures seamless communication between WMS and ERP systems.

Planning for Data Migration & System Downtime

Migrating data from legacy systems to an integrated platform requires careful planning. Establish a backup strategy and schedule the migration during low-activity periods to minimize disruptions.

Selecting an Integration Partner or Solution

A reliable integration partner or software solution can simplify the process, providing expertise and technical support to ensure a successful WMS ERP integration. Look for vendors with industry experience and proven success in similar projects.

WMS ERP Integration Methods

1. Direct Integration

Direct integration connects your WMS and ERP systems without intermediaries, enabling real-time data flow. This method offers speed and efficiency but requires custom development, making it ideal for companies with in-house IT expertise.

2. API-Based Integration

APIs facilitate seamless communication between WMS and ERP, ensuring flexibility and scalability. Businesses can integrate different software solutions while maintaining control over data exchange, making this a preferred method for modern operations.

3. Middleware & Third-Party Solutions

Middleware acts as a bridge between WMS and ERP, translating data formats for smooth interaction. Third-party solutions simplify integration, reducing development time while enhancing functionality and security.

4. Cloud-Based Integration

Cloud-based integration connects WMS and ERP via cloud platforms, improving accessibility and collaboration. With automatic updates, enhanced security, and reduced infrastructure costs, it’s a future-proof solution for growing businesses.

Each method has unique advantages—choosing the right one depends on your business needs and technical capabilities.

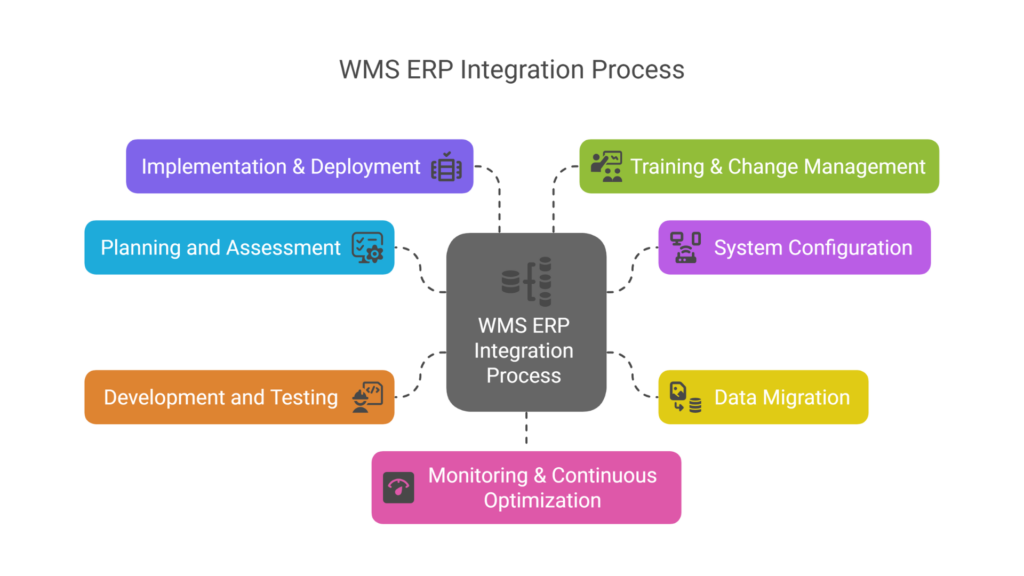

Step-by-Step Process for WMS ERP Integration

Successfully integrating your WMS and ERP requires a structured approach to minimize disruptions and maximize efficiency. Below is a step-by-step guide to ensure a seamless transition.

Step 1: Planning and Assessment:

Begin by evaluating your current systems, identifying pain points, and setting clear integration goals. A thorough needs assessment ensures alignment between business objectives and technology capabilities.

Step 2: System Configuration:

Configure both WMS and ERP to communicate effectively. This step may involve modifying workflows, setting up user roles, and ensuring compatibility between systems.

Step 3: Data Migration

Identify critical data points such as inventory, orders, and shipments. Ensure accurate data transfer from legacy systems to prevent discrepancies and maintain business continuity.

Step 4: Development and Testing

Develop integration modules, APIs, or middleware as needed. Rigorously test data flow, system interactions, and error handling to prevent future issues.

Step 5: Implementation & Deployment

Gradually roll out the integration, starting with a pilot phase to address any last-minute concerns. Ensure a smooth transition with minimal operational disruptions.

Step 6: Training & Change Management

Train employees on the new system to encourage adoption and reduce resistance. Clear communication and hands-on guidance will ease the transition.

Step 7: Monitoring & Continuous Optimization

Post-integration, continuously monitor system performance. Address potential bottlenecks and optimize workflows to ensure long-term efficiency and scalability.

Struggling with ERP implementation? Our experts are here to help!

Common Challenges in WMS ERP Integration & Solutions

Integrating a Warehouse Management System (WMS) with an ERP offers immense benefits, but the process comes with challenges.

1. Data Compatibility Issues:

Inconsistent data formats between WMS and ERP can lead to errors and inefficiencies. Standardizing data structures, using middleware, and implementing real-time synchronization help ensure seamless data flow.

2. System Downtime:

Integration may cause temporary disruptions. To mitigate risks, businesses should implement the integration in phases, conduct rigorous testing, and have a rollback plan in place.

3. User Adoption & Change Resistance

Employees may resist change due to unfamiliarity with new systems. Proper training, clear communication, and hands-on support encourage adoption and minimize productivity loss.

4. Integration Costs

While integration costs can be significant, businesses should focus on long-term ROI. Automating processes, reducing manual errors, and improving efficiency ensure cost savings and business growth over time.

Best Practices for a Successful WMS ERP Integration

A seamless WMS ERP integration requires careful planning and execution. Following best practices ensures a smooth transition and long-term success.

Aligning Business Processes:

Integration should align with business goals and IT capabilities. Mapping workflows and ensuring system compatibility help create a unified, efficient process.

Clear Communication in Team:

Open communication between IT, operations, and leadership prevents misunderstandings. Regular updates and cross-functional collaboration keep everyone on the same page.

Regular System Updates:

Routine maintenance and software updates prevent technical issues. Monitoring system performance helps identify potential bottlenecks early.

Providing Ongoing Training

User adoption is key to success. Continuous training, help desks, and user-friendly documentation ensure employees can fully utilize the integrated system.

Monitoring Key Performance (KPIs)

Tracking KPIs like inventory accuracy, order fulfillment speed, and system uptime provides insights into integration effectiveness, helping businesses optimize processes over time.

Conclusion:

Successfully integrating WMS and ERP systems is essential for optimizing warehouse operations, improving accuracy, and enhancing decision-making. Key steps include careful planning, system configuration, data migration, thorough testing, and ongoing monitoring. Addressing challenges like data compatibility, system downtime, and user adoption ensures a smoother transition.

For businesses looking for a seamless WMS ERP integration, partnering with an experienced provider is crucial. Infintrix Technologies specializes in tailored integration solutions, ensuring a streamlined process with minimal disruptions. With expert support and best practices, you can achieve a fully integrated system that drives efficiency and business growth.