Choosing the right ERP system for manufacturing industry can be challenging with so many options available. A good ERP can streamline operations, improve efficiency, and enhance decision-making.

Manufacturers face constant challenges—inefficient processes, inventory mismanagement, and rising production costs. Without the Best ERP for Manufacturing Industry, businesses struggle to streamline operations, control costs, and meet market demands. That’s where a robust ERP solution comes in, providing automation, real-time insights, and scalability to drive efficiency and growth.

This article explores the top 10 ERP systems for manufacturing in 2025, helping you choose the right software to optimize production, reduce waste, and boost profitability. Let’s dive in!

Table of Contents

- Why Manufactures Need an ERP System?

- The Role of ERP in Streamlining Operations

- Common Challenges in Manufacturing Without ERP

- Key Features to Look for in a Manufacturing ERP

- Top 10 Best ERP for Manufacturing Industry in 2025

- 1. NetSuite ERP

- 2. SAP S/4HANA – Best for Real-Time Analytics

- 3. Epicor ERP – Best for Mid-Sized Manufacturers

- 4. ERPNext – Best Open Source ERP for SMEs

- 5. Infor CloudSuite – Best for Industry-Specific Solutions

- 6. Acumatica Cloud ERP –Best for Seamless Integrations

- 7. Microsoft Dynamics 365 – Best for Seamless Integrations

- 8. Sage X3 – Best for Scalable and Flexible Manufacturing

- 9. IFS Cloud – Best for Industry-Specific Flexibility

- 10. Cetec ERP – Best for Cloud-Native, Seamless Integrations

- How to Choose the Best ERP for Your Manufacturing Business

- Factors to Consider Before Investing in ERP

- 1. Business Size & Scalability

- 2. Industry-Specific Requirements

- 3. User Experience & Adoption

- 4. Vendor Support & Reliability

- Cloud vs. On-Premise ERP – Which One is Right for You?

- Cloud ERP: The Future of Manufacturing

- On-Premise ERP: Full Control & Security

- Cost vs. ROI – Finding the Best Value ERP

- Understanding ERP ROI:

- Conclusion:

- What to Expect from ERP Trends in 2025 and Beyond

Why Manufactures Need an ERP System?

It is crucial to know for every manufacturer before implementing an ERP system in their business is how ERP system upscale manufacturing industry? If this question is straightforward for every manufacturing business should get ready to integrate an ERP system.

The Role of ERP in Streamlining Operations

Every manufacturing business needs an ERP system—without it, operations become inefficient, unmanageable, and prone to errors.

ERP streamlines processes, boosts productivity, and ensures seamless management. Modern ERP systems unite every single department—from inventory and procurement to production and sales—into a single platform. By automating workflows and providing real-time data, ERPs eliminate manual errors, accelerate decision-making, and enhance collaboration.

For example, a manufacturer can use ERP-driven analytics to optimize supply chain routes, reducing lead times by 20% or more.

Common Challenges in Manufacturing Without ERP

Without an ERP, manufacturers tackle these issues:

- Siloed Data: Disconnected systems lead to inefficiencies and miscommunication.

- Poor Inventory Management: Overstocking or stockouts disrupt production schedules.

- Compliance Risks: Manual tracking increases errors in regulatory reporting.

- Limited Scalability: Legacy systems have difficulty supporting growth or new markets.

Key Features to Look for in a Manufacturing ERP

When evaluating ERPs, prioritize:

- Production Scheduling: Tools for real-time resource allocation.

- Supply Chain Management: End-to-end visibility from suppliers to customers.

- Manage Quality: Compliance tracking and defect resolution.

- IoT Integration: Monitor machinery health and predictive maintenance.

- Advanced Analytics: AI-powered insights for demand forecasting.

Top 10 Best ERP for Manufacturing Industry in 2025

Here, a detailed list of the top 10 ERP Systems for Manufacturing System:

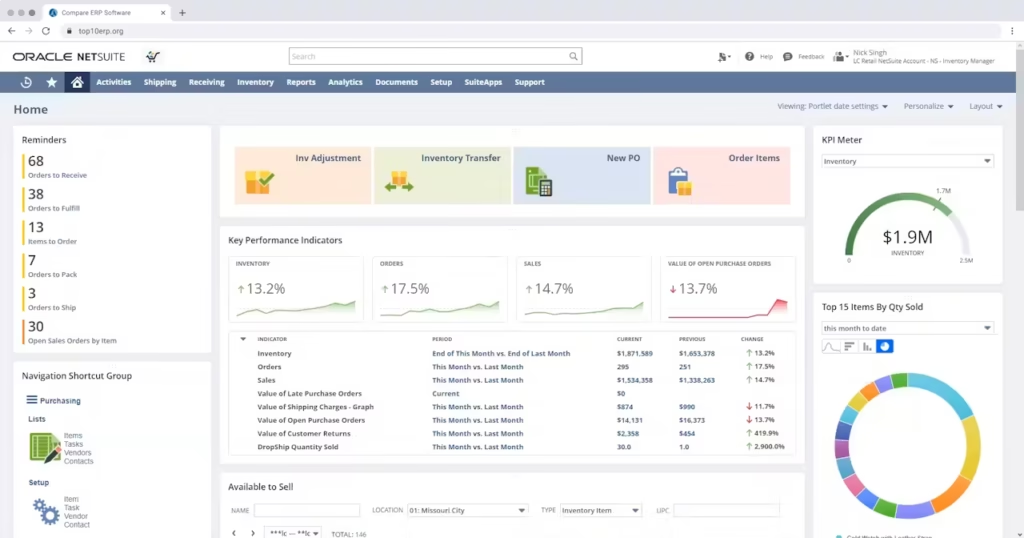

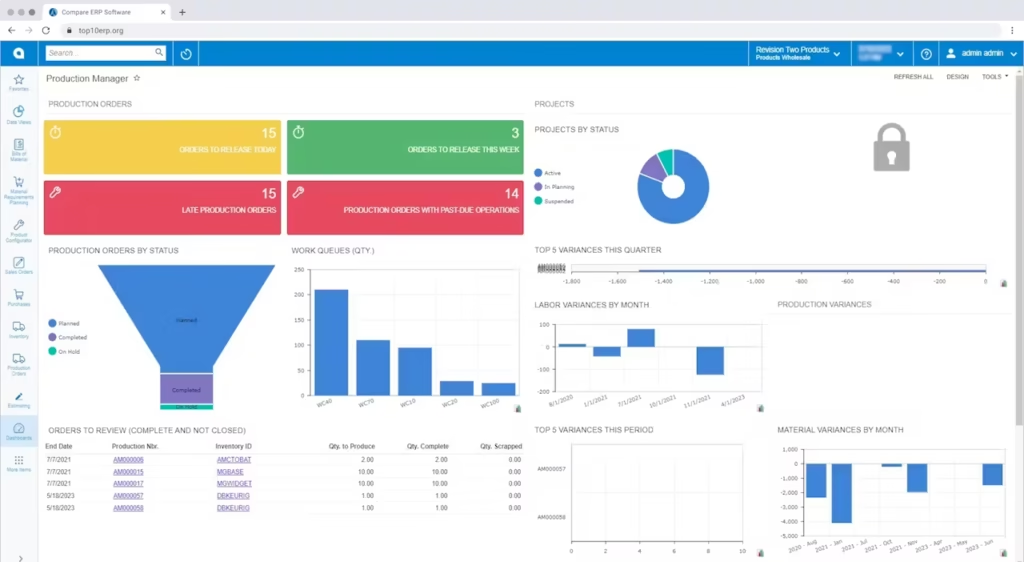

1. NetSuite ERP

NetSuite’s scalable modular architecture makes it the perfect ERP solution for startups and fast-growing manufacturers expanding into new markets. Its SuiteSuccess implementation accelerates deployment, reducing setup time by 30% for a faster go-live.

As the first ERP to offer full mobile support, NetSuite empowers manufacturers with real-time access to operations, inventory, and financials—anytime, anywhere.

| CategoryDetails | |

| Deployments | Cloud, On-Premise |

| Cost Per User | $125/month |

| Price Range | $10K – $100K |

| Retention Rate | N/A |

| Financing Options | Subscription |

| Fee to Implement | 12,000$ |

| Installs | 37,000+ |

| User Range | 10 – unlimited |

| Multi-Site | Yes |

| Multi-National | Yes |

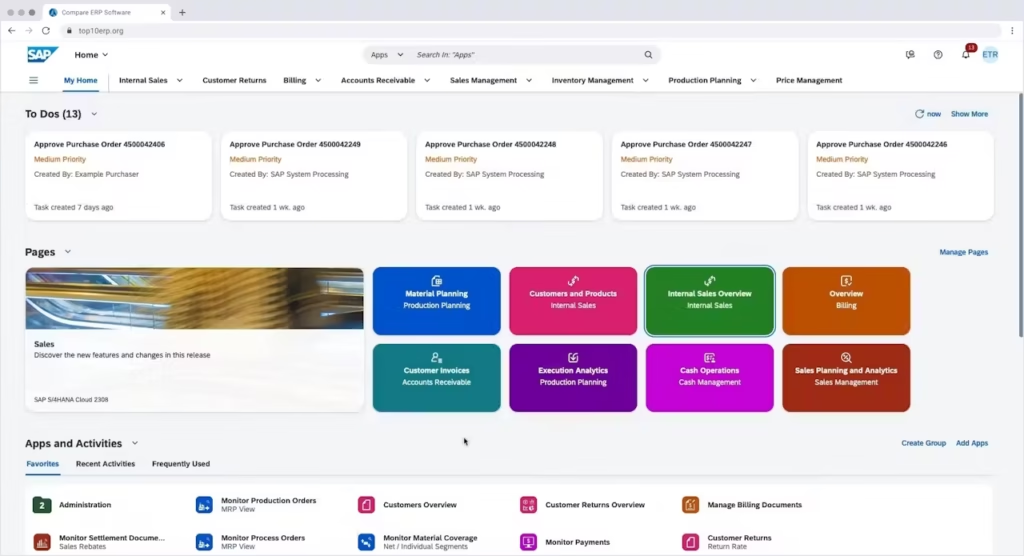

2. SAP S/4HANA – Best for Real-Time Analytics

SAP’s AI-driven ERP delivers unmatched flexibility and real-time intelligence, enabling manufacturers to instantly adjust production schedules in response to demand fluctuations. With advances in-memory computing, it accelerates data processing by up to 80%, ensuring faster decision-making and improved operational efficiency.

Designed for large enterprises, SAP’s ERP enhances predictive analytics, automation, and supply chain optimization, empowering businesses to stay agile, competitive, and future-ready.

| CategoryDetails | |

| Deployments | Cloud Only |

| Cost Per User | $200/month |

| Price Range | N/A |

| Retention Rate | 80% |

| Financing Options | Subscription |

| Fee of Implementation | 75,000$ |

| Installs | 10,000+ |

| User Range | 15-Unlimited |

| Multi-Site | Yes |

| Multi-National | Yes |

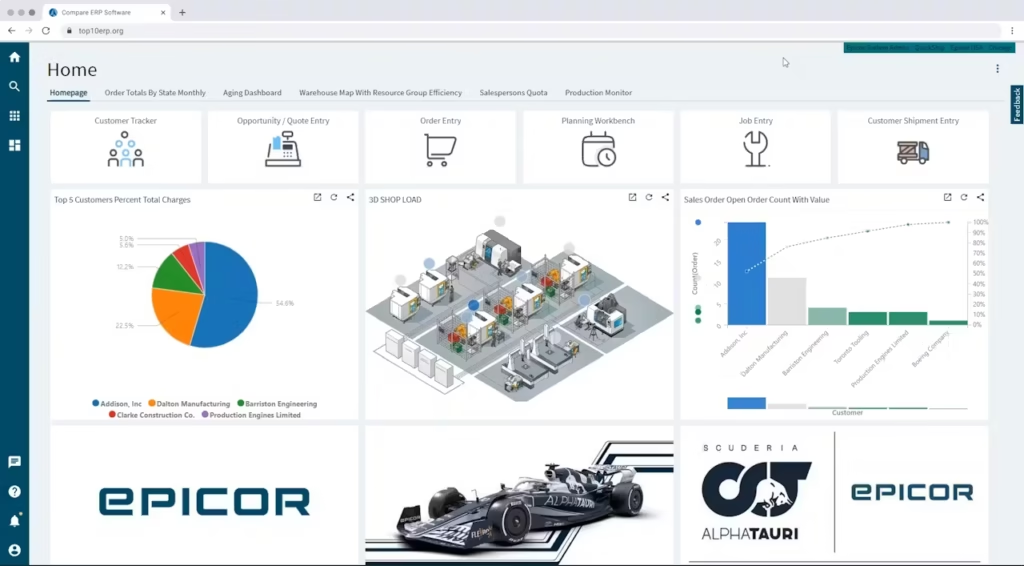

3. Epicor ERP – Best for Mid-Sized Manufacturers

Epicor’s intuitive user interface and powerful MRP tools empower SMEs to streamline production, reduce costs, and enhance efficiency. With built-in global compliance support, it simplifies multi-country operations, tax regulations, and industry standards, making it an ideal choice for growing manufacturers looking to scale seamlessly.

| CategoryDetails | |

| Deployments | Cloud & On-Premise |

| Cost Per User | $200/month |

| Price Range | $4K-$125K |

| Retention Rate | 95% |

| Financing Options | Lease, Subscription |

| Fee for Implementation | 50,000$ |

| Installs | 4500+ |

| User Range | 10-Unlimited |

| Multi-Site | Yes |

| Multi-National | Yes |

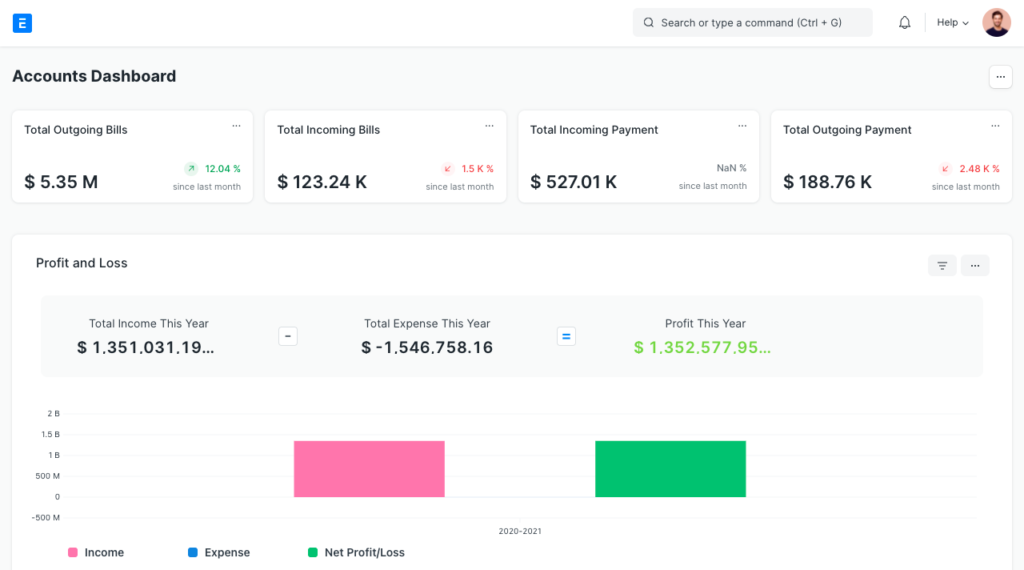

4. ERPNext – Best Open Source ERP for SMEs

ERPNext’s open-source flexibility and intuitive interface make it an ideal ERP solution for SMEs looking to streamline manufacturing, inventory, and financial processes. With powerful MRP tools, it enhances production planning, cost control, and real-time tracking.

Its built-in global compliance support simplifies multi-country operations, ensuring seamless tax management, reporting, and regulatory adherence for growing businesses. Get our ERPNext Implementation Services to grow faster in the future!

| CategoryDetails | |

| Deployments | Cloud & On-Premise |

| Cost Per User | $200/month |

| Price Range | $4K-$125K |

| Retention Rate | 95% |

| Financing Options | Lease, Subscription |

| Fee of Implementation | 50,000$ |

| Installs | 4500+ |

| User Range | 10-Unlimited |

| Multi-Site | Yes |

| Multi-National | Yes |

5. Infor CloudSuite – Best for Industry-Specific Solutions

Infor CloudSuite delivers tailored ERP solutions for industries like automotive, aerospace, and industrial manufacturing. With pre-configured workflows, it streamlines operations, compliance, and supply chain management.

Its AI-driven deep learning tools enable predictive maintenance, reducing downtime and optimizing asset performance, making it an ideal choice for manufacturers seeking industry-focused innovation.

| CategoryDetails | |

| Deployments | Cloud & On-Premise |

| Cost Per User | $150/month |

| Price Range | $25K-$525K |

| Retention Rate | N/A |

| Financing Options | Lease, Subscription |

| Installs | 2500+ |

| User Range | 5-1000 |

| Multi-Site | Yes |

| Multi-National | Yes |

6. Acumatica Cloud ERP –Best for Seamless Integrations

Acumatica’s mobile-first ERP platform offers seamless remote access, making it ideal for manufacturers with distributed teams and hybrid work environments. Its flexible pay-as-you-go pricing model ensures cost-efficiency, allowing businesses to scale effortlessly without high upfront investments.

With cloud and on-premise deployment options, Acumatica provides real-time data access, streamlined operations, and enhanced collaboration for modern manufacturers.

| CategoryDetails | |

| Deployments | Cloud & On-Premise |

| Cost Per User | $150/month |

| Price Range | $25K-$525K |

| Retention Rate | N/A |

| Financing Options | Lease, Subscription |

| Installs | 2500+ |

| User Range | 5-1000 |

| Multi-Site | Yes |

| Multi-National | Yes |

7. Microsoft Dynamics 365 – Best for Seamless Integrations

Microsoft Dynamics 365 seamlessly integrates with Power BI, Azure IoT, and Office 365, enabling real-time analytics, intelligent automation, and enhanced collaboration. Its modular design allows mid-sized manufacturers to scale features as needed, ensuring a flexible, cost-effective ERP solution that grows with their business.

| CategoryDetails | |

| Deployment | Cloud Only |

| Cost Per User | $175/month |

| Price Range | N/A |

| Retention Rate | 90% |

| Financing Options | Subscription |

| Fee of Implementation | $35,000 |

| Installs | 200+ |

| User Range | 10-Unlimited |

| Multi-Site | Yes |

| Multi-National | Yes |

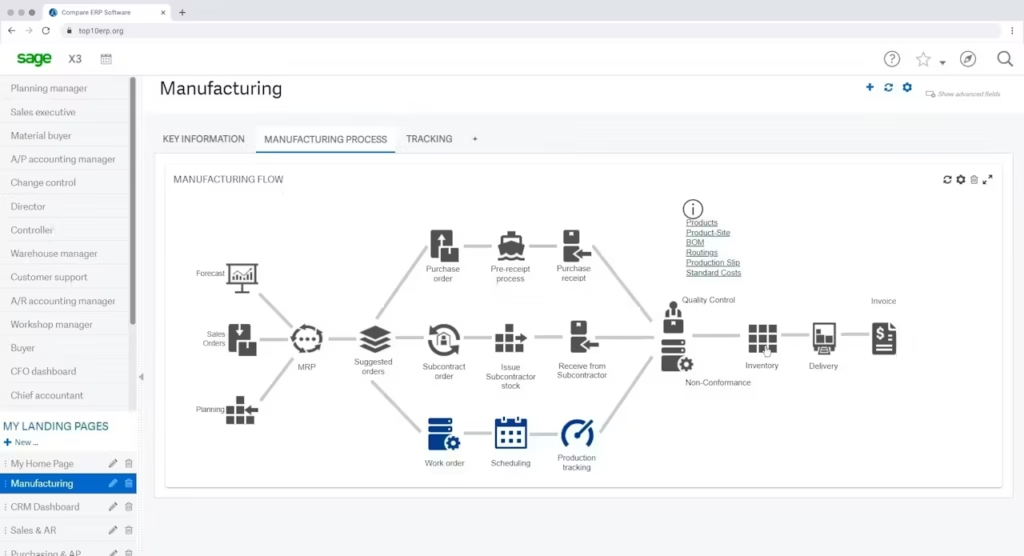

8. Sage X3 – Best for Scalable and Flexible Manufacturing

Sage X3 seamlessly integrates with third-party analytics, IoT solutions, and business applications, providing real-time insights, process automation, and enhanced collaboration.

Its scalable, modular design allows mid-sized manufacturers to customize features as needed, ensuring a flexible, cost-effective ERP solution that adapts to their growing business needs.

| CategoryDetails | |

| Deployment | Cloud Only |

| Cost Per User | $75/month |

| Price Range | $25K-$250K |

| Retention Rate | N/A |

| Financing Options | Finance, Subscription |

| Fee of Implement | $100,000 |

| Installs | 7000+ |

| User Range | 10-1000 |

| Multi-Site | Yes |

| Multi-National | Yes |

9. IFS Cloud – Best for Industry-Specific Flexibility

IFS Cloud seamlessly integrates with advanced analytics, IoT solutions, and enterprise applications, providing real-time insights, intelligent automation, and enhanced collaboration.

Its modular and industry-specific design enables mid-sized manufacturers to scale features as needed, ensuring a flexible, cost-effective ERP solution that evolves with their business growth.

| CategoryDetails | |

| Deployment | Cloud & On-Premise |

| Cost Per User | N/A |

| Price Range | N/A |

| Retention Rate | N/A |

| Financing Options | Finance, Subscription |

| Installs | 3,300+ |

| User Range | 10-up-to-end |

| Multi-Site | Yes |

| Multi-National | Yes |

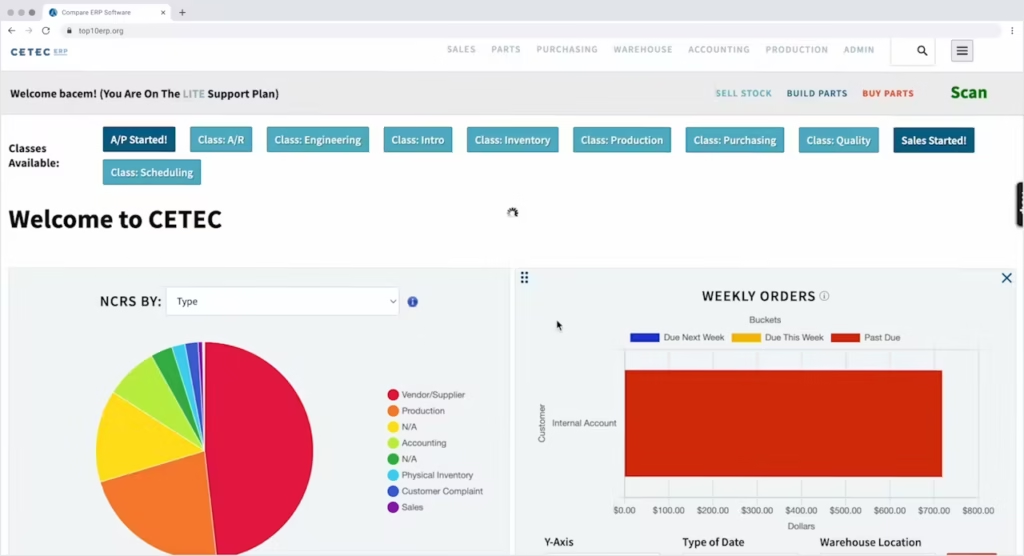

10. Cetec ERP – Best for Cloud-Native, Seamless Integrations

Cetec ERP seamlessly integrates with built-in business intelligence, cloud-based automation, and collaboration tools, providing real-time analytics and streamlined workflows.

Its scalable, all-in-one platform allows mid-sized manufacturers to adapt features as needed, ensuring a cost-effective, cloud-native ERP solution that grows with their business.

| CategoryDetails | |

| Deployment | Cloud & On-Premise |

| Cost Per User | $50/month |

| Price Range | $3K-$40,000K |

| Retention Rate | 95% |

| Financing Options | Subscription |

| Fee to Implement | $0 |

| Installs | 250+ |

| User Range | 5-unlimited |

| Multi-Site | Yes |

| Multi-National | Yes |

How to Choose the Best ERP for Your Manufacturing Business

Selecting the best ERP solution is a critical decision for any manufacturing business. The right ERP can streamline operations, improve efficiency, enhance decision-making, and drive profitability. However, with numerous options available, choosing the best ERP requires careful consideration of multiple factors. From deployment options and industry compliance to cost, scalability, and ROI, this section will guide you through the key aspects to evaluate before making an investment.

Factors to Consider Before Investing in ERP

1. Business Size & Scalability

- SMEs: Small and mid-sized manufacturers may prioritize affordability, ease of implementation, and essential features without unnecessary complexity.

- Large Enterprises: Bigger companies often need advanced customization, AI-driven analytics, and seamless integration with existing systems.

2. Industry-Specific Requirements

- Different industries have unique compliance needs. For example:

- Pharmaceutical & Food Processing: Must adhere to FDA and ISO regulations for product safety.

- Automotive & Aerospace: Require strict quality control and supply chain visibility.

- Textile & Apparel: Need real-time inventory tracking and demand forecasting.

- Choosing an ERP tailored to your industry-specific needs ensures better compliance, smoother implementation, and optimized workflows.

3. User Experience & Adoption

- A complicated ERP can lead to frustration, resistance, and productivity loss among employees.

- Ensure the ERP has an intuitive interface, mobile accessibility, and customizable dashboards to enhance usability.

- Invest in training and onboarding programs to help employees adapt quickly and maximize ERP benefits.

4. Vendor Support & Reliability

- 24/7 support, comprehensive training resources, and dedicated account management are crucial for ERP success.

- Look for vendors that offer regular software updates, bug fixes, and compliance enhancements to ensure your ERP stays current.

Cloud vs. On-Premise ERP – Which One is Right for You?

Choosing between Cloud ERP and On-Premise ERP is another critical decision that depends on data security, customization, and scalability needs.

Cloud ERP: The Future of Manufacturing

- Lower upfront costs, as there’s no need for expensive hardware.

- Automatic updates ensure you always have the latest features and security patches.

- Remote access enables teams to manage operations from anywhere, making it ideal for distributed teams and global supply chains.

- Scalable and flexible, perfect for fast-growing businesses that require rapid adjustments.

- Examples: NetSuite, Acumatica, ERPNext.

On-Premise ERP: Full Control & Security

- Data remains in-house, offering greater control and security, which is essential for industries with strict data privacy regulations (e.g., defense, finance, and government contracts).

- Highly customizable, allowing manufacturers to tailor the ERP system to their specific needs.

- Requires a dedicated IT team for maintenance, updates, and troubleshooting.

- Higher upfront costs but could be cost-effective in the long run for established businesses that need long-term stability.

- Examples: SAP S/4HANA, Microsoft Dynamics 365, Epicor.

Cost vs. ROI – Finding the Best Value ERP

While Cloud ERPs typically cost $150–$250 per user per month, it’s essential to look beyond just the price and evaluate the return on investment (ROI).

Understanding ERP ROI:

- Reducing Inventory Waste: A well-implemented ERP can cut excess inventory by 15%, potentially saving a company $500K annually.

- Increasing Production Efficiency: Automated workflows and predictive maintenance reduce downtime and improve productivity by 20-30%.

- Lowering Operational Costs: By optimizing procurement, logistics, and labor management, companies can save thousands of dollars each year.

- Improved Decision-Making: Real-time analytics help manufacturers identify trends, mitigate risks, and optimize production scheduling, leading to higher profitability.

Conclusion:

With Industry 4.0 revolutionizing manufacturing, ERP systems are becoming more than just data management tools—they are now intelligent, predictive, and automation-driven solutions.

What to Expect from ERP Trends in 2025 and Beyond

- AI and Machine Learning: ERP systems will increasingly use AI-powered analytics to provide real-time insights, predictive demand planning, and automated decision-making.

- IoT (Internet of Things) Expansion: IoT-enabled ERPs will allow for real-time equipment monitoring, predictive maintenance, and enhanced quality control.

- Sustainability Tools: More ERPs will integrate carbon footprint tracking, energy consumption analysis, and circular supply chain management, helping manufacturers meet eco-friendly goals.

- Blockchain for Supply Chain Transparency: Manufacturers will leverage blockchain-powered ERPs for secure, transparent transactions and traceability of materials.